Table of Contents

V2 AIO Box Assembly page

Introduction

So, you've just received your kit. Please read this page to assemble properly your kit.

You may notice some small differences beetween the pictures and your own kit but it's mostly the same for the build.

If you have some questions, feel free to ask : mailto:adrien.grelet@gmail.com.

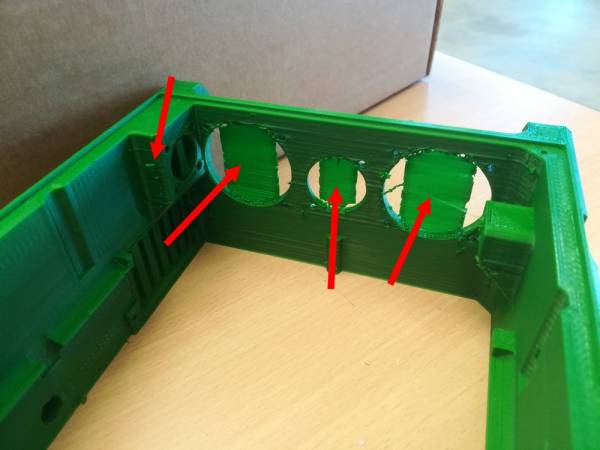

Step 1 : Clean the parts

The printed parts come with some supports you'll have to remove with a plier and cut the extra material with a well sharpened knife.

On the picture it's just the main zones you'll have supports, but check the entire parts to clean them.

Also, on the CNC parts, even I've checked them, you can have some burrs you can easily remove by filing the edges.

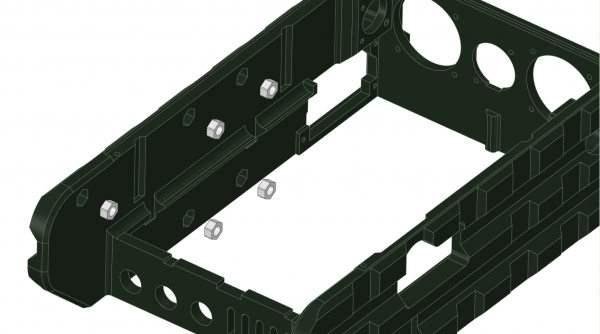

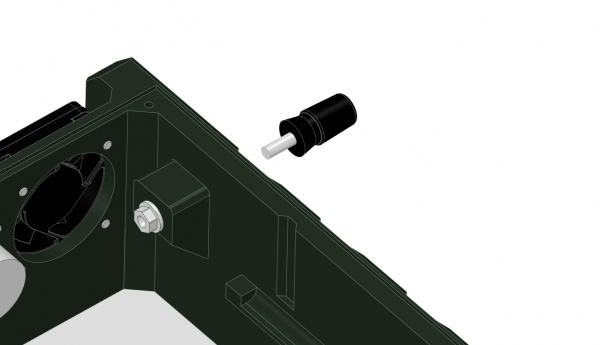

Step 2 : Install M5 nuts for the accessory port

| Item | Quantity | Note |

|---|---|---|

| AIO box | 1 | |

| M5 nuts | 5 |

Use some pliers if you need to install the nuts for future accessory port. If you think this can be a bit too loose, don't hesitate to glue the nuts.

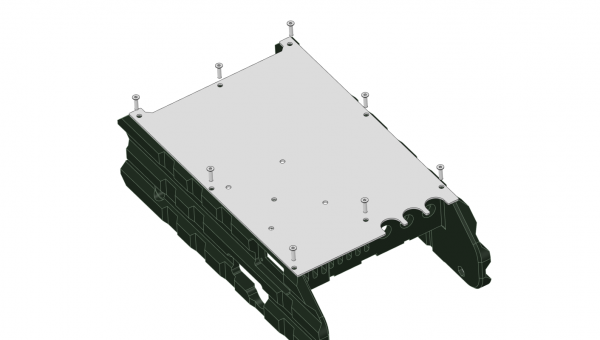

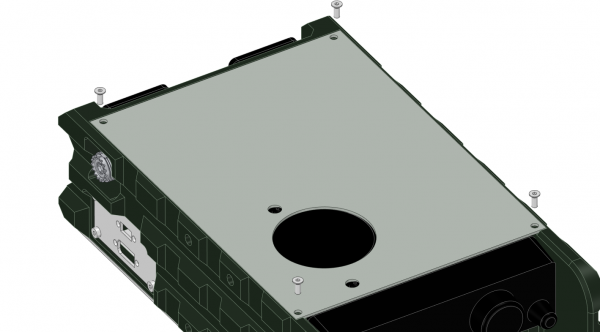

Step 3 : Mount the heatsink and the base plate

| Item | Quantity | Note |

|---|---|---|

| PLAQUE_DESSOUS | 1 | Base plate in alumium |

| Aluminium Heatsing | 1 | |

| TFX03/012ZN | 8 | M3 countersunk head, 12mm long |

| TFX03/08ZN | 1 | M3 countersunk head, 8mm long |

First of all, screw the 12mm screws to attach the bottom plate on the printed box. Mind the position of the plate, the 3 “U” shapes are for the 3 switchs you will install at the end.

After that, screw the heatsink on the plate with the 8mm screw. Be careful to have the M3 tappered hole on the left side (it'll be easier to install the thermal switch). Also take care to install the heatsink parallel with the box.

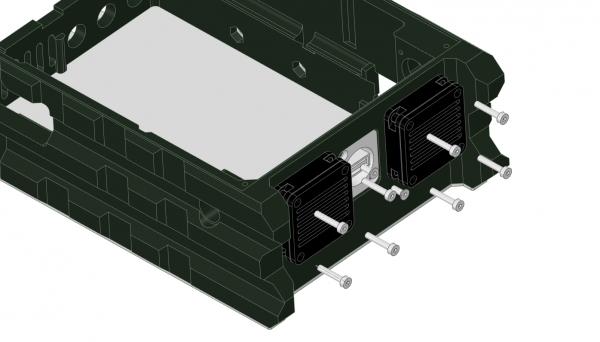

Step 4 : Install the DC fans and RJ45 socket

| Item | Quantity | Note |

|---|---|---|

| DC fan | 2 | with filtered cover |

| RJ45 socket | 1 | |

| TFX03/08ZN | 2 | M3 coutersunk head, 8mm long |

| TCX03/16ZN | 8 | M3 standard head, 12mm long |

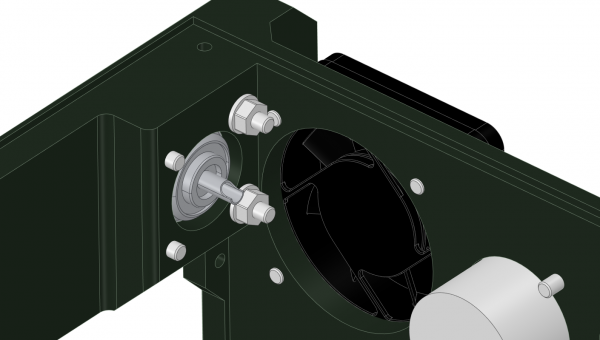

Step 5 : Install SO-239 socket and ground banana connector

| Item | Quantity | Note |

|---|---|---|

| Banana ground connector | 1 | |

| SO-239 socket | 1 | |

| TCX03/012ZN | 2 | M3 standard head, 16mm long |

| TCX03/08ZN | 2 | M3 standard head, 8mm long |

| M3 spacer | 2 | |

| M3 nut | 2 |

You can't make any mistake. The 12mm screws with the spacers and nuts are on the biggest holes. Please keep in mind that on one nut you'll use it later to connect the ground of the connector to your radio.

The banana socket has it's proper screw and nut to attach. Here to, keep in mind that you'll need to connect to the groung of your radio.

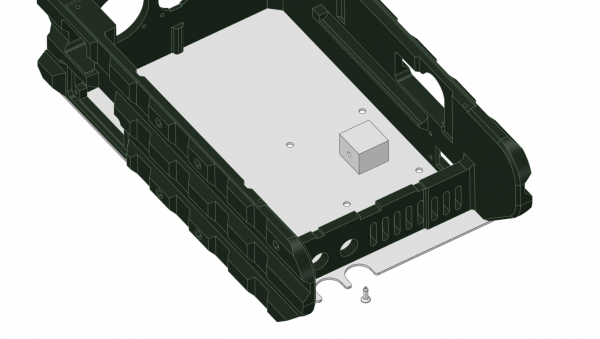

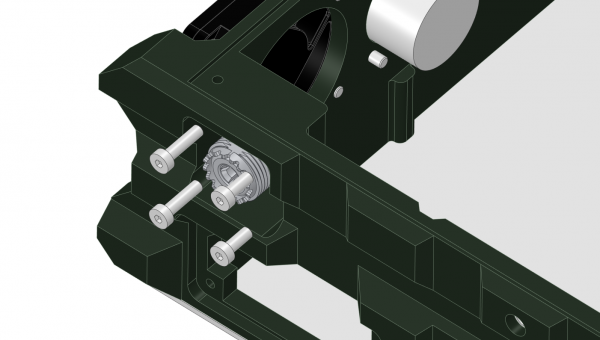

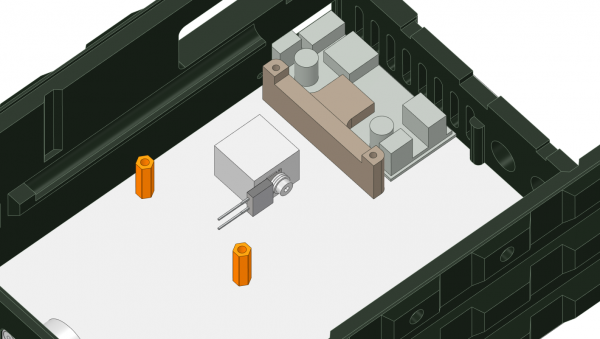

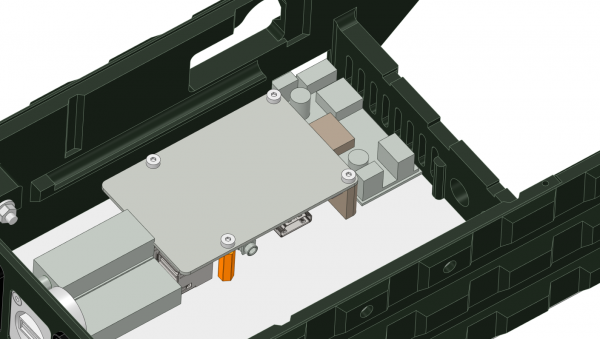

Step 6 : Install the step down converter and the Raspberry Pi

| Item | Quantity | Note |

|---|---|---|

| 16mm spacer | 2 | |

| PINCE_REGULATEUR | 1 | printed part |

| DC stepdown | 1 | |

| Foam | 1 | Piece of foam to protect stepdown |

| TFX03/08ZN | 4 | M3 countersunk head, 8mm long |

| TCX03/08ZN | 5 | M3 standard head, 8mm long |

| M3 spacer | 3 |

Don't forget to screw the thermal switch before installing the RPI !

Solder 2 wires of about 20cm on the thermal switch and then install it on the heatsink. Use 3 M3 spacers and a standard head 8mm screw.

Also, before installing the DC converter, prepare the wiring and solder it (on both Raspberry and power supply side).

Screw by the bottom the 16mm spacers and the printed part with the 4 countersunk head screws. Add a piece of foam just under the DC stepdown to avoid any contact with the aluminium plate. Adjust the thickness of the foam to have the DC stepdown well stuck.

Then, install the Raspberry upside down, make sure that the central processor is in contact with the heatsink. You can add some thermal paste in order to increase the heat transfer (not supplied).

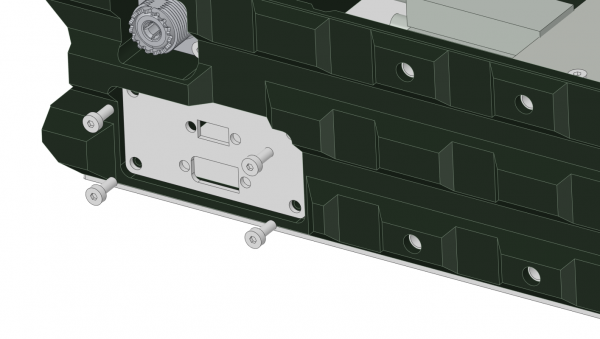

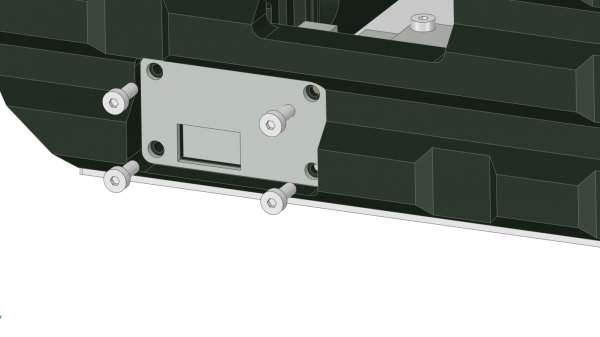

Step 7 : Install side plates

| Item | Quantity | Note |

|---|---|---|

| Left side plate | 1 | aluminium part |

| Right side plate | 1 | aluminium part |

| TCX03/08ZN | 8 | M3 standard head, 8mm long |

Step 8 : Modify your radio for internal battery switch

Warning : if your radio is still under warranty, you should consider that this mod will void the warranty as you're going to modify your radio. Proceed at your own risk.

This step is important because you'll leave connected the USB soundcard of the Raspberry Pi. By doing this, if the internal battery pack of the radio is still connected, you'll have some current that will be draining by the USB soundcard (I haven't made some measures, but at least there is an activity led which will be turned on anytime). Maybe it's just some mA but if you leave your AIO box unattended for some weeks, this can discharge the internal battery pack.

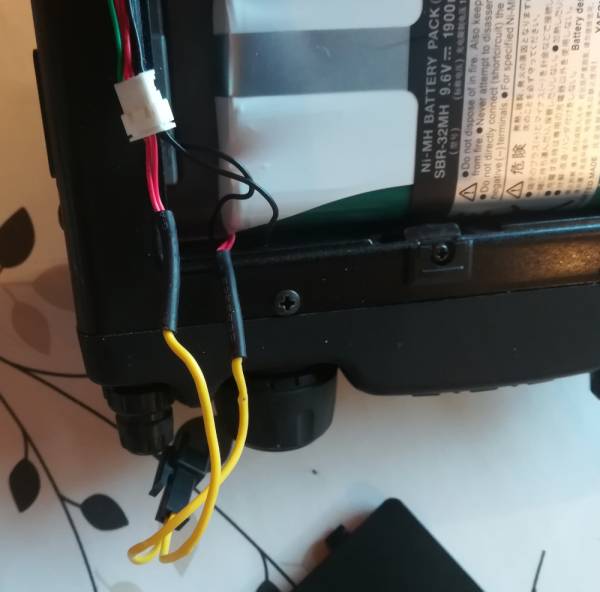

So, this step is to cut the + wires of the battery pack to insert the SW1 switch. By doing this, you'll be able to cut the internal power supply when you'll not use the radio.

The battery cover has to be cut a bit in order to let 2 wires to go through the back of the radio. I've used a soldering iron to melt the plastic and then a cutter to clean the cover :

After that, I've cut the 2 red wires on the battery pack side. By doing this, you're not going to modify the wires of the radio, but the wires of the battery pack, which can be changed if needed in the future :

I've crimped the Molex connector at the end of the 2 wires, in order to unplug it easily off the box. The wires will then go directly to the SW1 switch.

It's not more complicated than that, but I do recommend it to prevent from internal battery pack discharge.

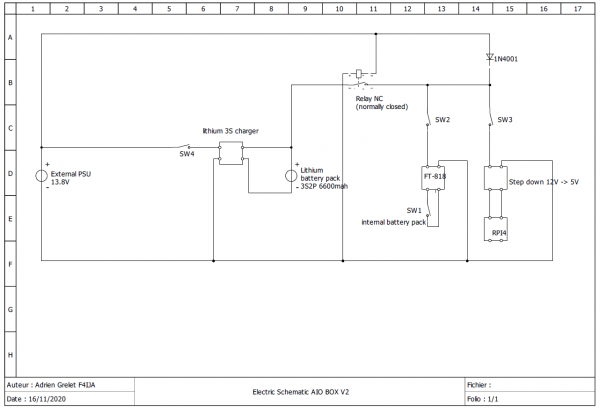

Step 9 : Wiring

This is an example of what you can make to have your AIO box working like mine. The relay acts as a security to avoid destroying your battery pack when powering to external PSU.

electric_schematic_aio_box_v2.pdf

Feel free to adjust if you want another behaviour.

Below is how I've put the switches in the case :

You'll find some pictures on how it's wired in my case :